Contact with us via sales@gdsiao.com

Siao is a reliable one-stop supplier dedicated to providing next-generation automated, intelligent, and digitalized equipment systems for the metal wire rod coils and slit coils processing industry. In 2022, we established our manufacturing facility in Shaoguan, Guangdong, covering an area of 10,000 m². The facility is equipped with multiple independent production workshops, each with a scientifically planned layout that ensures the smooth and efficient execution of various production stages, including wire drawing, coiling, and coil packaging. This strategic design enhances production efficiency by clearly defining key areas such as raw material processing, assembly, and debugging zones, all of which are optimized for production management and quality control.

The facility layout provides ample space for equipment placement, production line configuration, and the storage of both raw materials and finished products, meeting the needs of large-scale production requirements.

All raw materials used in production comply with GB/T 2976-2020 national standards, ensuring their durability and reliability for high-quality manufacturing.

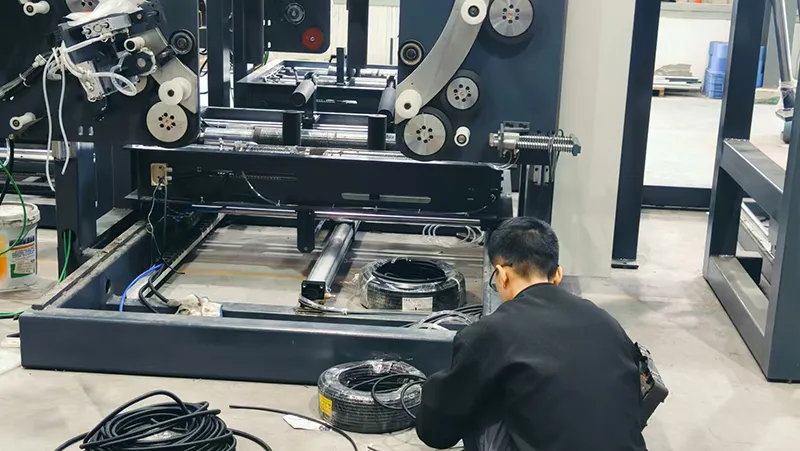

Before shipment, most of the wire coil wrapping machines and metal coil handling systems undergo a pre-assembly check in this area to ensure everything is functioning correctly. During this process, they are assembled and run to confirm that they operate smoothly and meet the required standards.

In the testing area, we focus on ensuring key aspects such as secure packaging of the coils, emergency stop braking times, and proper lubrication of all moving parts. We also check for oil leakage, ensure that safety devices are sensitive and reliable, and verify that the hydraulic system and all fasteners are secure. The electrical systems are thoroughly tested for ease of operation and reliability. Only after confirming all these aspects are in perfect working order do we proceed with shipping the equipment to the customer.

- The manufacturing process adheres to the requirements of the GB/T 43780-2024 national standard for quality management systems, ensuring that all produced equipment meets design specifications and quality expectations.

- The design of our equipment complies with GB/T 16855.1-2008 national standards, ensuring that safety measures are integrated into every step. This includes features like emergency stop systems, protective devices, and other critical safeguards to protect operators.

Rigorous quality testing system

We have established a rigorous quality testing system that spans from raw material sourcing to final product shipment. Each stage of production undergoes strict quality control checks. For instance, we carefully screen raw material suppliers and inspect the quality of materials before they are used. During production, random sampling is performed at every step to ensure that our wire coil packaging machines meet quality standards.

Quality certifications and recognition

We have earned quality management system certification and hold prestigious honors, including technology-based SME, and provincial specialized and innovative SME status. These certifications demonstrate our commitment to maintaining high product quality standards and industry expertise.