We begin by learning about your production setup in detail, wire characteristics, packaging requirements, plant environment, material type, drawing method, drawing speed and strength, wire diameter range, and coil dimensions (inner diameter, outer diameter, height). This helps us develop a packaging solution tailored specifically to your process, ensuring the equipment meets your functional expectations and integrates smoothly into your existing operations.

Based on the initial consultation, our engineers develop a design plan that considers the full scope of your wire packaging process, from smooth wire transfer and accurate positioning to consistent wrapping results.

- Control system optimization

The electrical control system can be adapted to simplify operation and include smart monitoring features with built-in fault diagnostics. - Efficiency for different production scales

For smaller operations, we offer compact machine layouts to minimize resource usage. For high-volume production, the design focuses on fast, continuous packaging to meet throughput demands. - Compatibility with wire types

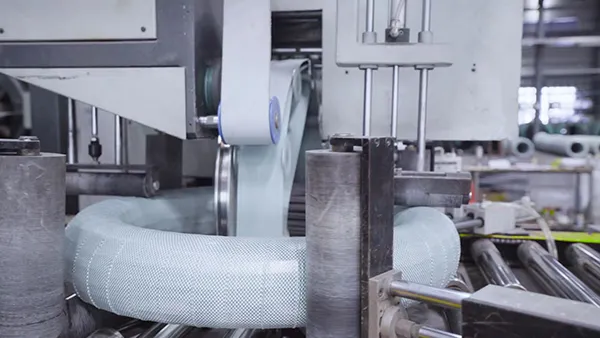

Custom gripping devices, conveyor tracks, and packaging methods are tailored to suit different wire characteristics. Whether the wire is soft and easily deformed or stiff and heavy, the system ensures stable packaging and reduces the risk of damage. - Special packaging requirements

If you require specific packaging materials or formats, such as plastic film, paper wrapping, coiling, or bundling, we customize the solution accordingly. Our wire coil packaging machines can also include advanced marking systems to apply product information, batch numbers, or tracking codes directly onto the packaged wire, supporting inventory control and traceability.

Once the design is finalized, the manufacturing team begins production using high-precision equipment and skilled fabrication techniques. Each component is tested to ensure it meets the required specifications. During assembly, strict process standards are followed to maintain overall machine accuracy and ensure long-term reliability.

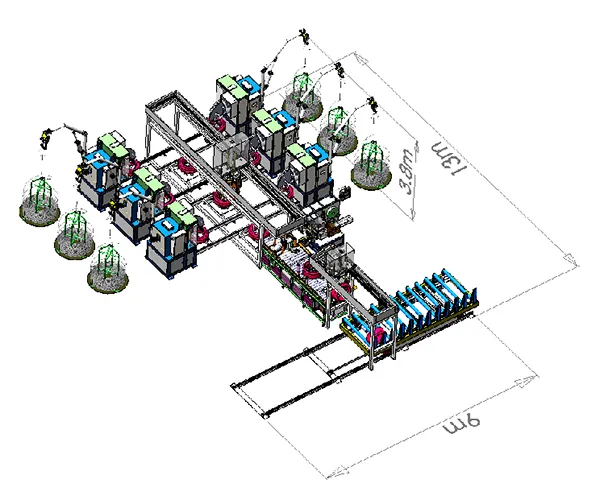

If a wire drawing machine is already part of your production line, we can design a packaging solution that adapts to your existing layout. By analyzing the position of your wire processing equipment and the available space, we ensure the proposed system integrates seamlessly into your current workflow without requiring major adjustments.

Once the customized wire packaging or drawing solution is built, performance testing is carried out either in a simulated setup or directly at your production site. During this stage, we verify main parameters such as packaging speed, consistency, and stability. If needed, our engineers will fine-tune settings such tension control or wrapping alignment to ensure the wire wrapping equipment operates smoothly and meets the requirements defined during the design phase.

Once the wire coil packaging equipment passes final inspection, it is delivered to your facility along with full service support. This includes operator training, spare parts supply, remote technical assistance, and optional future upgrades. We aim to provide a complete, end-to-end experience that supports your operations long after installation.

- Email: sales@gdsiao.com