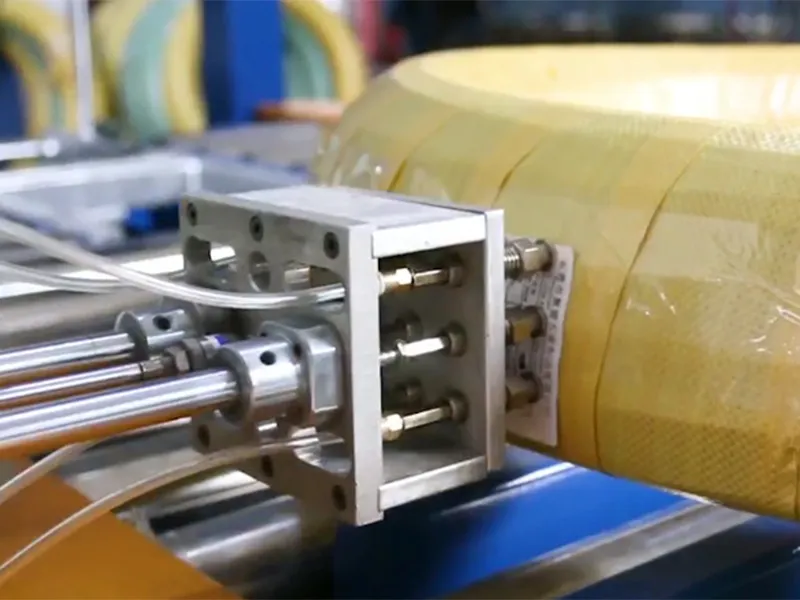

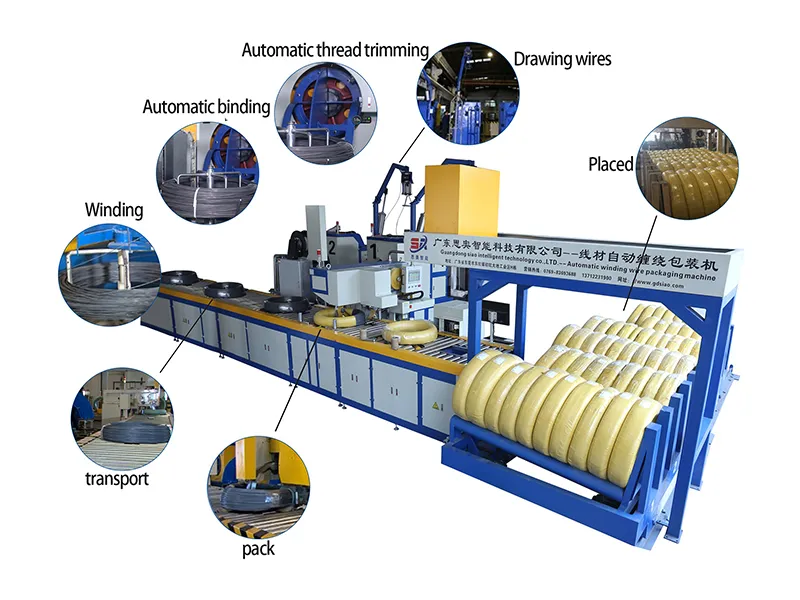

This fully automated wire drawing and packaging line integrates manual or automated coil feeding (via AGV, forklift, or overhead crane) with a configurable wire drawing module, tailored to your production capacity and process requirements. Once the wire reaches the preset weight, the system performs automatic cutting, strapping with PP or PET bands, automated transfer to the wrapping unit, through-the-eye wrapping using woven tape, PE film, or kraft paper, followed by weighing, labeling, and specification-based storage.

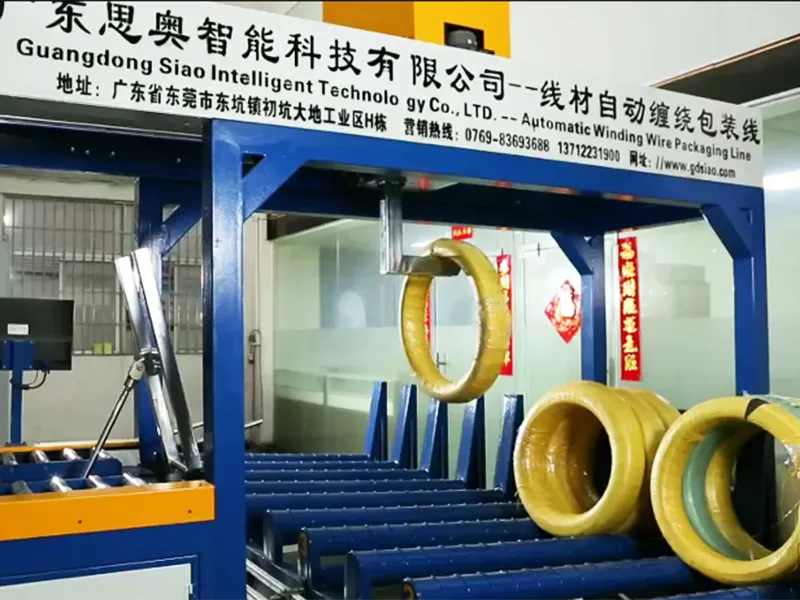

All label data is instantly uploaded to your ERP or MES system for real-time data sharing and production traceability. The entire line requires only one operator to load the wire and thread the die as the rest of the process is fully automated, delivering scalable and efficient coil production.

This wire drawing and packaging line is used for drawing and packaging stainless steel, low-carbon steel, and high-carbon steel wire. After packaging, the coils are tightly secured and neatly arranged, offering moisture, dust, rust, and scratch protection, ensuring product quality during storage and transportation.

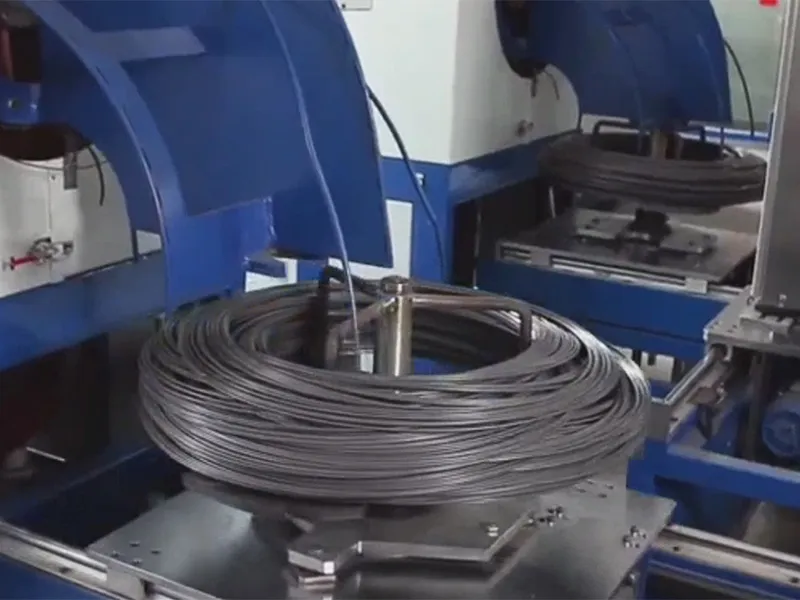

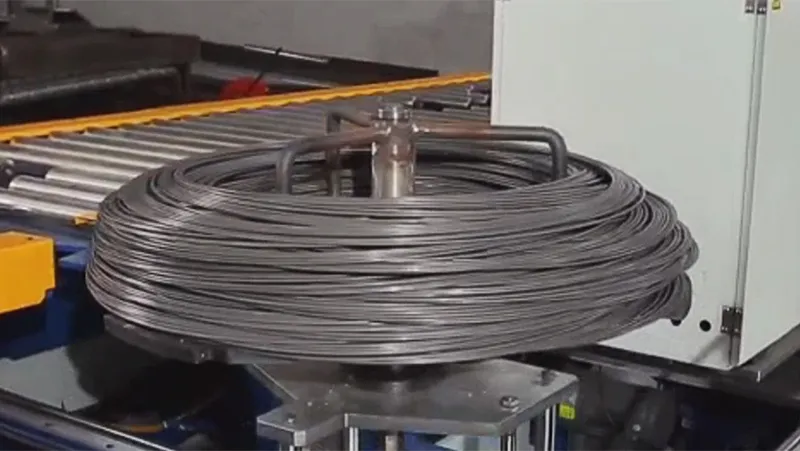

Before packaging

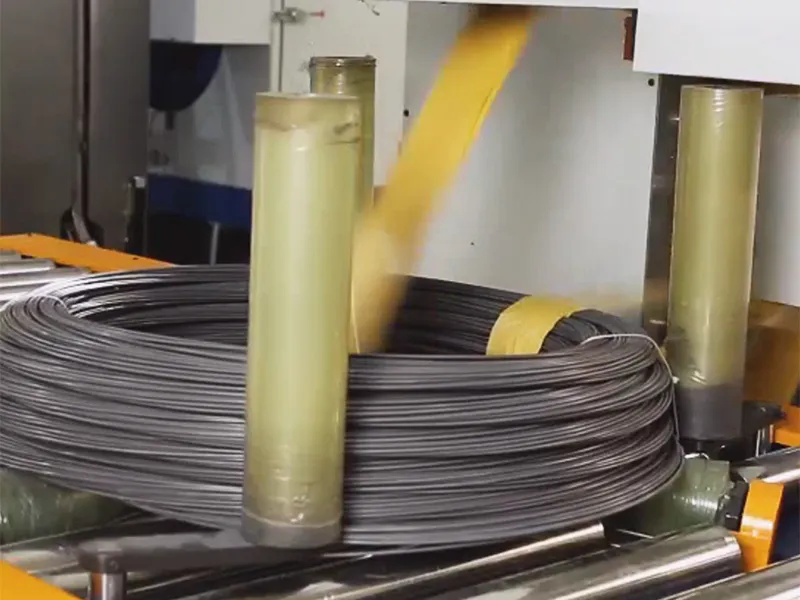

Before packaging  After packaging

After packaging